Relined manholes are better than before

The manhole relining process is able to transform manholes that have been badly sealed or corroded and reinvigorates them into a better-than-new condition.

The manhole relining process is able to transform manholes that have been badly sealed or corroded and reinvigorates them into a better-than-new condition.

The relining process carried out by the FITT Resources servicing team, removes the corroded material, fills the gaps with mortar, and chemically seals the manholes to prevent future damage.

The servicing team carries out inspections, grading and relining services to councils, giving the manholes an upgrade so that they can last longer than in their original state.

How manholes get damaged

Under low pH-level conditions, acidophilic bacteria in the sewer system feed on sulfur in hydrogen sulfate gas, which releases sulfuric acid.

Sulfuric acid can corrode mortar, steel, ductile iron and concrete – sometimes, up to 25mm of concrete in a year.

The problem is compounded by errors in the initial construction of the manholes.

Manhole construction involves stacking rings of concrete on top of each other, which must be joined together.

FITT Resources Head of Regional Servicing, Richard Arthur, said if the manhole hadn’t been constructed correctly, then there might be gaps between the rings, allowing stormwater to enter the system.

FITT Resources Head of Regional Servicing, Richard Arthur, said if the manhole hadn’t been constructed correctly, then there might be gaps between the rings, allowing stormwater to enter the system.

Mr Arthur said, “When these joins are in this condition, roots can get in, which can actually open the gaps up and make them wider.

“A small town could have around 10,000 manholes. When you get heavy rain, as often happens in Australia, the rainwater seeps through these unsealed manholes and gets into the sewer system.”

Sewer systems are only designed to handle wastewater, which goes to a sewage treatment works to get treated. Stormwater doesn’t need to be treated and is generally just drained away into river systems.

Mr Arthur said the excess water could overload the plant, which could be expensive for operators.

“If the stormwater ends up in the sewage treatment plant, which is not designed for those storm conditions, then the plant can’t cope.

“The water volumes can interfere with the aerobic processes that form a part of the treatment of wastewater. This requires the use of chemicals to fix the problem, which is costly.” Mr Arthur said.

The relining process

To resolve the problem of unsealed and corroded manholes, FITT Resources servicing team has a four stage process.

1. The team enters the manhole and cleans with a high-pressure water blast. They cut out any roots – which are treated in order to kill them – and get rid of all the corroded material.

treated in order to kill them – and get rid of all the corroded material.

2. They then complete necessary localised repairs at inlet and outlet pipes, benching, joins and under the lids.

3. FITT Resources applies a calcium aluminate mortar, Sewpercoat, which breaks up the cycle of biogenic corrosion and stops the process at the chemical level.

⋅Calcium aluminates prevent the metabolism of acid-generating bacteria and maintain a pH level of over 3.

⋅25mm of Sewpercoat is sprayed on via an air-driven spinning head from a mortar pump.

4. Finally, the servicing team enters the manhole for the third time to hand finish using steel trowels and to compress all spray that has been applied.

Why FITT does it best

Why FITT does it best

Councils have a legal requirement to inspect their assets every five years. Ongoing maintenance saves a lot of money and keeps things in a good condition.

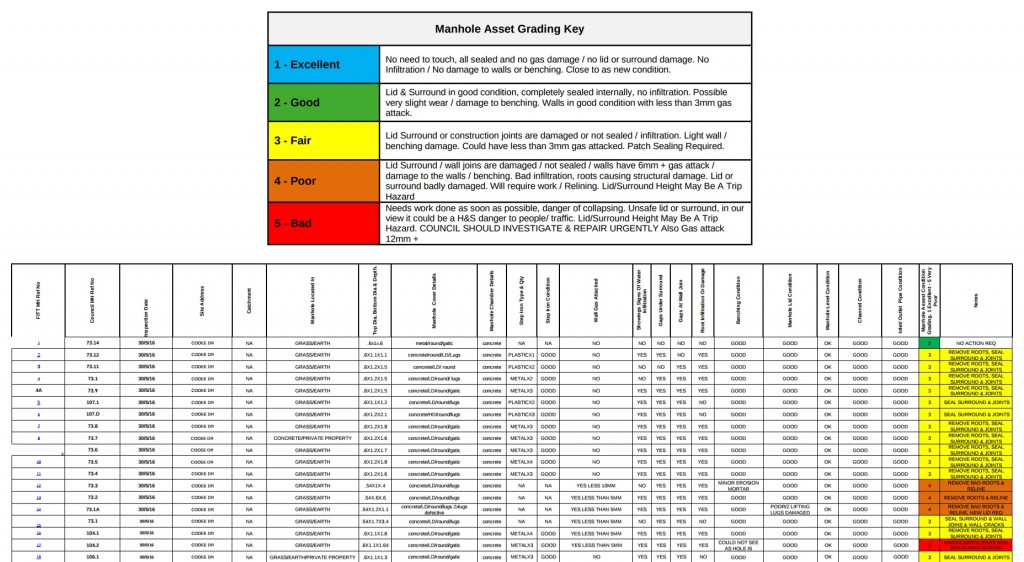

FITT Resources do inspections of manholes to gauge their condition, compiling the data into a spreadsheet with grades so that councils can see the maintenance priorities.

The grading system is colour-coded and has five ratings, so it is clear which manholes need the most work.

Mr Arthur said, “Every five years councils have to report on the condition of the manholes, and as some don’t always have the manpower to do that work themselves, they need to bring in some help.

“A lot of the assets out there are ageing and require work and inspections to return them to a good condition.”

FITT Resources recently won manhole relining tenders for Port Macquarie-Hastings, Kempsey and Narrandera Councils.

The servicing team has completed manhole relining work for around 25 other local councils.

Mr Arthur said that FITT Resources was competitive because of a combination of efficiency, skilled, fast working crews, and top-notch equipment.

The range of services offered by FITT Resources, particularly their expertise in pump work, enabled them to effectively service regional areas.

“We’re a wee bit different to other companies in that we can provide these competitive services, which allows us to go to regional areas more often,” Mr Arthur said.

“Our knowledge of the pump industry means we can work on pump stations or carry out jobs on sewer treatment plants and water treatment plants in these areas.”

Mr Arthur said the services offered by FITT Resources could reclaim the damaged equipment in a way that was cheaper than replacing them.

“These manholes have been there for 100 years and we have got a process that brings them back to a nice new condition. They have a coat that will protect them for even longer in the future – so it’s an upgrade.”