Split seal makes the job easier

The newest Chesterton pump seal can be installed in under 20 minutes, thanks to its split cartridge design and innovative auto-alignment features.

The newest Chesterton pump seal can be installed in under 20 minutes, thanks to its split cartridge design and innovative auto-alignment features.

The 442C seal is all about speedy installation and repair, while still offering increases in reliability. The new design improves on the Chesterton 442 model, while resolving problems faced by conventional seals.

FITT Resources director Jason Lynch said that some conventional component, split and cartridge seals often posed difficulties for the installer.

“With a standard seal, you have to pull the pump apart to change it,” Mr Lynch said.

“The 442C is really designed as a maintenance enhancement so you can get seals on and off without disassembling the pump. This results in more productivity, as you can get your equipment back online quicker.

“Certainly, with larger equipment, the 442C enables us to have a leaking seal replaced and back up and running again within an hour, whereas other designs might take a day or two to get it working again.

The seal is field repairable with a spare parts kit, avoiding long delays in which the product is sent back to the manufacturer.

The 442C overcomes the limits of conventional split seal designs, which tend to have complicated installations and poor reliability.

The seal comes in four parts, an inner rotary holder and outer gland assembly, both of which are split into two halves. The faces are encapsulated in the rotary holder and outer gland eliminating the need to handle the faces when installing.

The two halves of the seal faces fit together with new V-shaped grooved joins, ensuring the ends are aligned when it is assembled. This has improved the seal capabilities so it doesn’t weep at start up and run-in.

When the halves of the rotary holder are tightened the faces automatically align, avoiding the need for any fiddly adjustments by the installer.

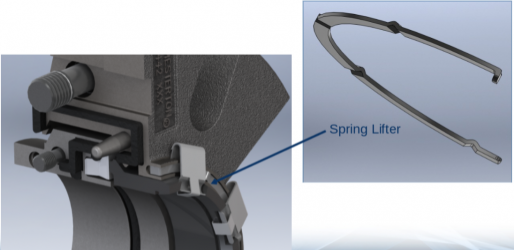

A further design introduction is the spring lifter. The spring lifter supports the springs, allowing space between the faces as the outer gland is installed. When the gland halves are tightened, the lifter releases the springs, energising the seal faces.

Applications

Mr Lynch said the 442C was used in a wide range of industries such as water and sewage, irrigation, mining and mineral processing.

Mr Lynch said the 442C was used in a wide range of industries such as water and sewage, irrigation, mining and mineral processing.

“We’re now delving into using these in slurry applications, where they have frequent seal change out due to the aggression of the product and the operation of their rotating equipment.

“With the 442C, there is greater reliability but it also gives you the ability to change seals out quickly, maintaining production.”

“Chesterton has been a market leader with its split seal technology for years. And the new enhancements to the 442 has set a new benchmark.

“FITT Resources focus on the reliability and availability of our customers equipment. Industry now has less people doing more work, and new innovative technology really enables us to offer our customers a solution for increased equipment availability while still offering fantastic reliability.”

FITT Resources is phasing out the older Chesterton 442, though they will still be supporting it by providing spare parts. New installs and replacements will use the 442C.

For more information please don’t hesitate to contact the team at FITT Resources.