The dos and don’ts of dewatering pump arrangement

There are a number of details to consider when it comes to optimising the operation of your dewatering pump. Although straightforward, it is not uncommon to find these simple factors being overlooked on construction sites, resulting in poor performance of the pump and system.

Pump arrangement

How your pump is arranged within site conditions should be the first consideration when installing a dewatering pump, said Chris Molloy, Dewatering Business Manager at FITT Resources.

“Ensure that your pump does not have the ability to burrow itself into sand or clay. This can occur if the velocity of the pump begins to remove sediment from the area close to the pump inlet.

“This is a common problem at construction sites and can quickly lead to early failure of the pump due to excessive wear, recirculation and shaft deflection.

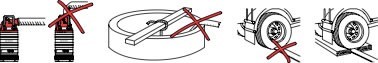

“This can be avoided quite simply by placing the pump on a bed of coarse gravel or a plank of wood.

“As well as this, the pump can be hung freely by a rope or chain, or put into a cut-down and perforated oil drum. The drum will act as a primary strainer and the larger area will prevent the drum from burrowing into the sediment.

Avoid sharp bends on the hose

Sharp bends, kinks and pinching of the hose can significantly reduce the capacity of the pump, says Mr Molloy.

“To avoid this, turn the pump’s discharge connection so the hose doesn’t begin with a kink.

“Where a pump is discharging at 90 degrees and the discharge fitting is vertical, the hose will kink. To fix this, simply rotate the discharge so that it is horizontal.”

Discharge being rotated to prevent the hose from kinking – Discharge hose kinking as it exits the sump – How to protect the discharge hose from damage due to traffic.

Tandem connection

Grindex pumps also supply connecting flanges that can connect two pumps together in a series. This is achieved by simply removing the strainer and installing the tandem connector.

“The advantage of this is achieving a higher pumping head. This is advantageous in high head applications and where space prevents larger pumps to be used.

“It is also important that the hoses are equipped with check valves. This will prevent wear on the pumps if a failure should occur in the operation system and controls and result in water running back from high heads,” says Mr Molloy.

Long distance pumping

Long distance pumping

Tandem pump connections can also be used if water needs to be pumped over a long distance.

“This can be managed quite simply by installing a dedicated collection pit into which the water can be pumped. The pit should be equipped with another pump that passes the water on.

“This technique can also be used for dewatering large areas with several pumps spread out over a long distance, each pumping into a collection pit.

“The collection pit should then be equipped with a larger pump that pumps the water away from the site,” says Mr Molloy.